According to the surface condition and production processing requirements of electroplating equipment, it is a key step to obtain high-quality coating by selecting several appropriate steps to repair the surface of parts, so as to make the parts have smooth surface. In the pre-treatment process, the common main equipment are grinding, grinding and polishing machine, brush milling machine, automatic sandblasting machine, roll milling machine and various fixed fixed grooves. Electroplating is an important process in all production processes. According to the requirements of the parts, one or several kinds of single metal materials or aluminum alloy electroplating processing technology are selected to carry out electroplating or dip plating on the parts to ensure corrosion resistance, wear resistance and beautiful appearance. Electroplating equipment in the treatment of common machinery and equipment are important, there are a variety of fixed fixed tank, barrel plating tank, hanger, electric hanging basket, etc. The post-treatment process is to polish, polish, passivate, dye, dry, hermetic, dehydrogenation and so on. One or more kinds of production processes must be selected to make the parts meet the quality requirements. The post-treatment process of plating is common, and the important machinery and equipment are grinding, grinding and polishing machine, various fixed fixed grooves, etc.

Process requirements of electroplating equipment

1. Coating and sheet metal material, coating and coating in the middle, need to have high-quality bonding.

2. The coating should be fine, smooth and even in thickness.

3. The coating shall have the specified thickness and porosity to be avoided as far as possible.

4. The coating shall have various specified index values, such as gloss, strength, conductivity, etc.

5. Plating time and temperature of the whole electroplating process, management and decision of coating thickness specification.

6. The operating temperature is - 10 ℃ ~ 60 ℃.

7. The input standard voltage is 220 V ± 22 V or 380 V ± 38 v.

8. The water purification equipment of electroplating equipment is very large, and the noise should not exceed 80dB (a).

9. The air humidity (RH) should not exceed 95%.

10. The COD content of source water is 100 mg / L ~ 150 000 mg / L.

- Home page

-

High end electroplating equipment

- Automatic galvanizing production line

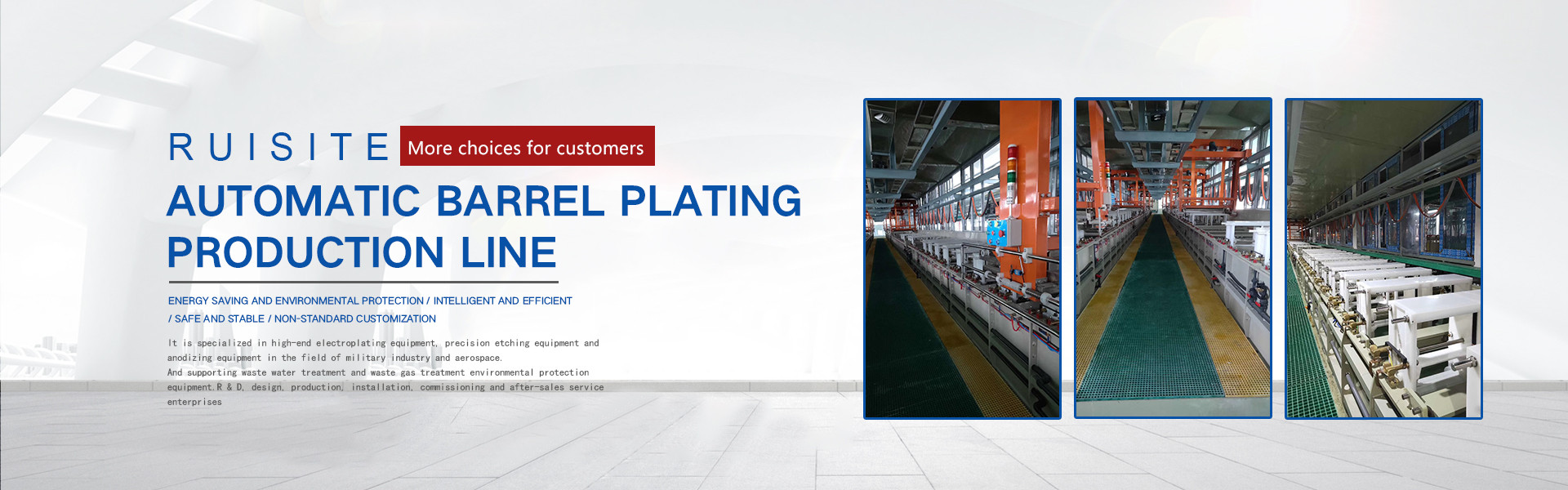

- Automatic barrel plating production line

- Continuous electroplating production line

- PCB electroplating production line

- Gold plating production line

- Silver plating production line

- Copper plating production line

- Nickel plating production line

- Tin plating production line

- Chromium plating production line

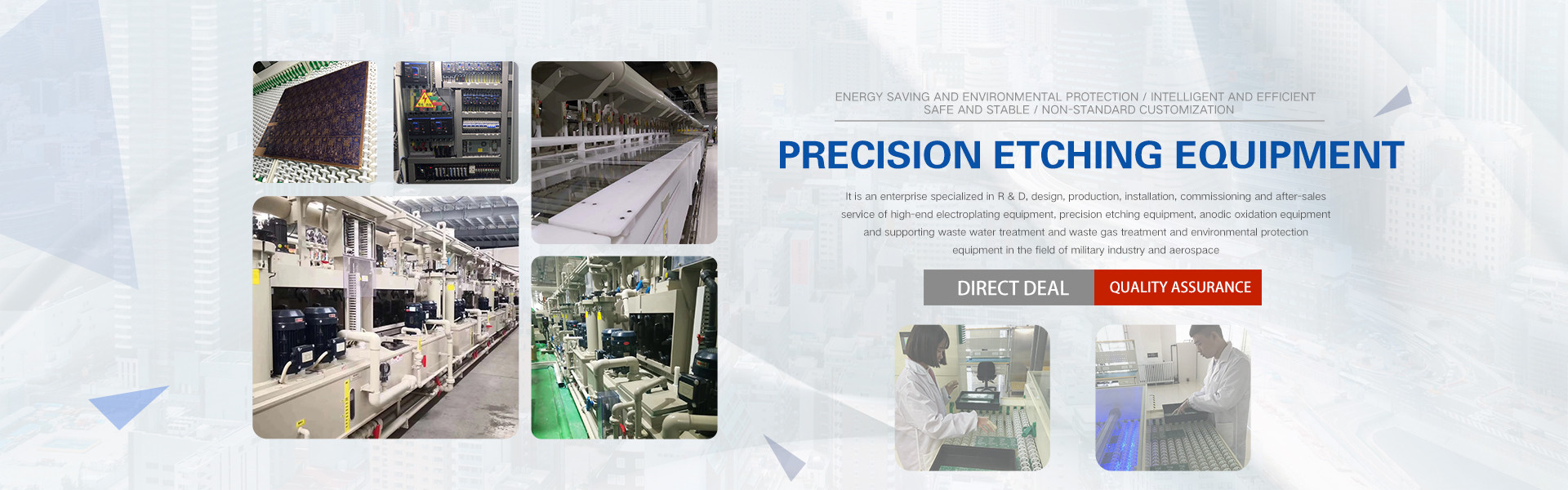

- Precision etching equipment

- Product Center

- Customer case

- news information

- Company profile

- contact us

-

中文(簡體)

中文(簡體)

Hot keywords